Picture frames accumulate in homes over time, often relegated to storage once their original purpose has been fulfilled. Rather than discarding these potentially valuable decorative elements, transforming them into functional serving trays represents both an environmentally conscious choice and a creative opportunity. This conversion process not only extends the life of existing materials but also creates bespoke decorative accessories that complement interior design schemes whilst providing practical utility.

The transformation from picture frame to decorative tray requires careful planning, appropriate materials, and precise execution techniques. Whether working with vintage wooden frames discovered at antique markets or modern plastic variants found in charity shops, the fundamental principles remain consistent. Understanding material properties, structural requirements, and finishing techniques ensures professional-quality results that rival commercially produced alternatives.

Contemporary interior design trends increasingly favour sustainable practices and personalised decorative elements. Frame-to-tray conversions align perfectly with these preferences, offering homeowners the opportunity to create unique pieces that reflect personal aesthetic preferences whilst maintaining functional requirements for entertaining and home organisation.

Essential tools and materials for picture frame to decorative tray conversion

Professional-quality results depend entirely upon selecting appropriate tools and materials for each specific frame type and intended use. The conversion process demands precision cutting, secure adhesion, and durable finishing materials that withstand regular handling and cleaning. Investment in quality equipment significantly impacts both the construction process and final product durability.

Basic tool requirements include measuring equipment, cutting implements, adhesives, and finishing materials. However, the specific grade and type of each component varies considerably based on frame construction, intended tray dimensions, and anticipated usage patterns. Understanding these variables prevents costly mistakes and ensures optimal project outcomes.

Professional-grade sandpaper selection: 120-grit to 400-grit progression

Surface preparation forms the foundation of any successful frame conversion project. Sandpaper selection directly influences paint adhesion, finish quality, and overall project durability. Professional woodworkers recommend a progressive grit sequence beginning with 120-grit for initial surface preparation, advancing through 220-grit for smoothing, and concluding with 400-grit for final finishing.

Coarse 120-grit paper effectively removes existing finishes, scratches, and surface imperfections whilst creating sufficient texture for primer adhesion. Medium 220-grit paper eliminates scratches created during initial sanding whilst maintaining adequate surface tooth for subsequent coatings. Fine 400-grit paper produces the smooth surface required for professional paint application and eliminates visible sanding marks.

Wood adhesives: PVA glue vs epoxy resin for structural integrity

Adhesive selection represents a critical decision point that affects both structural integrity and project longevity. PVA glue offers excellent bonding strength for wood-to-wood joints, extended working time for positioning adjustments, and easy cleanup during application. However, its limited moisture resistance makes it unsuitable for trays intended for beverage service or humid environments.

Epoxy resin provides superior bonding strength across diverse material combinations, exceptional moisture resistance, and gap-filling properties that accommodate less-than-perfect joint alignment. The trade-off involves shorter working time, more complex mixing requirements, and challenging cleanup procedures. Professional craftspeople typically reserve epoxy for high-stress applications or mixed-material bonds.

Glass cutting tools: wheeled cutters and safety equipment requirements

Glass removal and cutting procedures require specialised tools and comprehensive safety protocols. Wheeled glass cutters feature carbide or diamond cutting wheels that score glass surfaces with consistent pressure and depth. Quality cutters include oil reservoirs that lubricate cutting wheels, reducing friction and improving score quality.

Safety equipment includes protective eyewear, cut-resistant gloves, and appropriate work surfaces that prevent glass damage during handling. Proper technique involves single-pass scoring with consistent pressure, followed by controlled breaking over a straight edge. Multiple scoring attempts weaken glass structure and increase breakage risk.

Primer selection: zinsser bulls eye 1-2-3 vs kilz adhesion bonding

Primer selection significantly impacts paint adhesion, coverage uniformity, and long-term durability. Zinsser Bulls Eye 1-2-3 offers excellent adhesion to glossy surfaces, fast drying times, and compatibility with both water-based and oil-based topcoats. Its versatility makes it suitable for diverse frame materials and finishing systems.

Kilz Adhesion primer specifically targets challenging surfaces including glossy paints, ceramic tiles, and metal components. Its advanced bonding agents create mechanical adhesion that exceeds traditional primers on difficult substrates. However, longer drying times and stronger odours may influence selection for indoor projects.

Frame assessment and preparation techniques for optimal conversion

Thorough frame assessment determines project feasibility, material requirements, and appropriate conversion techniques. Different frame types present unique challenges and opportunities that influence design decisions and construction approaches. Understanding these characteristics enables informed decision-making throughout the conversion process.

Structural integrity assessment involves examining joint quality, material condition, and overall frame stability. Frames with loose joints, significant damage, or compromised structural elements may require repair or reinforcement before conversion. Early identification of these issues prevents project delays and ensures satisfactory outcomes.

Victorian era frame restoration: identifying gold leaf vs faux gilding

Victorian frames often feature elaborate gilded finishes that require careful evaluation before conversion. Authentic gold leaf application creates a distinctive appearance characterised by subtle variations in colour and texture, whilst maintaining remarkable durability over time. Faux gilding techniques produce more uniform colour distribution but may show wear patterns that reveal underlying base materials.

Professional assessment involves examining finish consistency, wear patterns, and underlying material visibility. Gold leaf typically maintains colour integrity in protected areas whilst showing wear at high-contact points. Faux finishes demonstrate more uniform degradation patterns and may exhibit colour shifts towards yellow or green tones. This distinction influences restoration approaches and material selection for conversion projects.

Modern plastic frame modifications: polystyrene vs polypropylene handling

Contemporary plastic frames utilise diverse polymer formulations that require specific handling techniques and compatible materials. Polystyrene frames offer excellent dimensional stability and accept paint readily but demonstrate brittleness that increases breakage risk during modification. Polypropylene frames provide superior impact resistance and flexibility but present adhesion challenges for paint and primer systems.

Material identification involves simple tests including flexibility assessment and surface texture evaluation. Polystyrene exhibits minimal flexibility and smooth surface characteristics, whilst polypropylene demonstrates significant flexibility and may have textured surfaces. Understanding these differences enables appropriate primer selection and modification techniques that ensure successful conversion outcomes.

Antique wooden frame evaluation: dovetail joint inspection methods

Antique wooden frames frequently employ traditional joinery techniques that influence structural integrity and conversion possibilities. Dovetail joints represent superior craftsmanship and provide exceptional strength for frame corners. Proper evaluation involves examining joint tightness, wood condition around joint areas, and overall structural stability.

Visual inspection reveals joint quality through gap assessment and alignment verification. Well-constructed dovetail joints show minimal gaps and maintain precise alignment despite age-related wood movement. Compromised joints may exhibit visible gaps, misalignment, or movement when pressure is applied. These conditions require repair or reinforcement before conversion to ensure adequate structural integrity for tray applications.

Glass panel removal: safety protocols for glazing points and putty

Glass removal procedures require systematic approaches that prioritise safety whilst preserving both glass and frame integrity. Traditional glazing points secure glass panels within frame rabbets and must be carefully removed to prevent frame damage. Modern spring clips or plastic tabs offer easier removal but may require specific tools or techniques.

Putty removal involves softening compounds through gentle heating or chemical softeners, followed by careful scraping with appropriate tools. Heat guns provide controlled warming that softens putty without damaging surrounding wood, whilst chemical softeners penetrate hardened compounds for easier removal. Complete putty removal ensures proper base preparation for tray conversion.

Advanced construction methods for tray base integration

Professional tray conversion requires secure base integration that provides adequate structural support whilst maintaining aesthetic appeal. The choice between solid base panels and planked constructions influences both appearance and functionality. Solid bases offer smooth surfaces ideal for decorative treatments, whilst planked designs create visual interest and accommodate dimensional movement in wooden frames.

Base material selection significantly impacts both structural performance and finishing options. Medium-density fibreboard provides smooth surfaces and dimensional stability but requires proper sealing to prevent moisture absorption. Solid wood bases offer natural beauty and superior durability but may experience dimensional changes with humidity variations. Plywood alternatives balance stability with strength whilst offering various surface veneer options.

Attachment methods must accommodate anticipated loads whilst maintaining frame integrity. Mechanical fasteners provide immediate strength and allow disassembly for repairs, whilst adhesive bonds create seamless connections that distribute loads effectively. Combination approaches utilise both methods for maximum security and performance. Proper fastener selection considers material compatibility, load distribution, and aesthetic requirements.

Dimensional planning ensures proper fit within frame rabbets whilst accommodating material thickness variations. Professional installation requires precise measurements that account for frame tolerances and base material expansion. Dry-fitting procedures verify compatibility before final installation and identify potential issues that require adjustment. This methodical approach prevents costly mistakes and ensures professional results.

Professional craftspeople understand that proper base integration forms the foundation of successful tray conversion, requiring attention to both structural requirements and aesthetic considerations.

Surface treatment and finishing applications for decorative trays

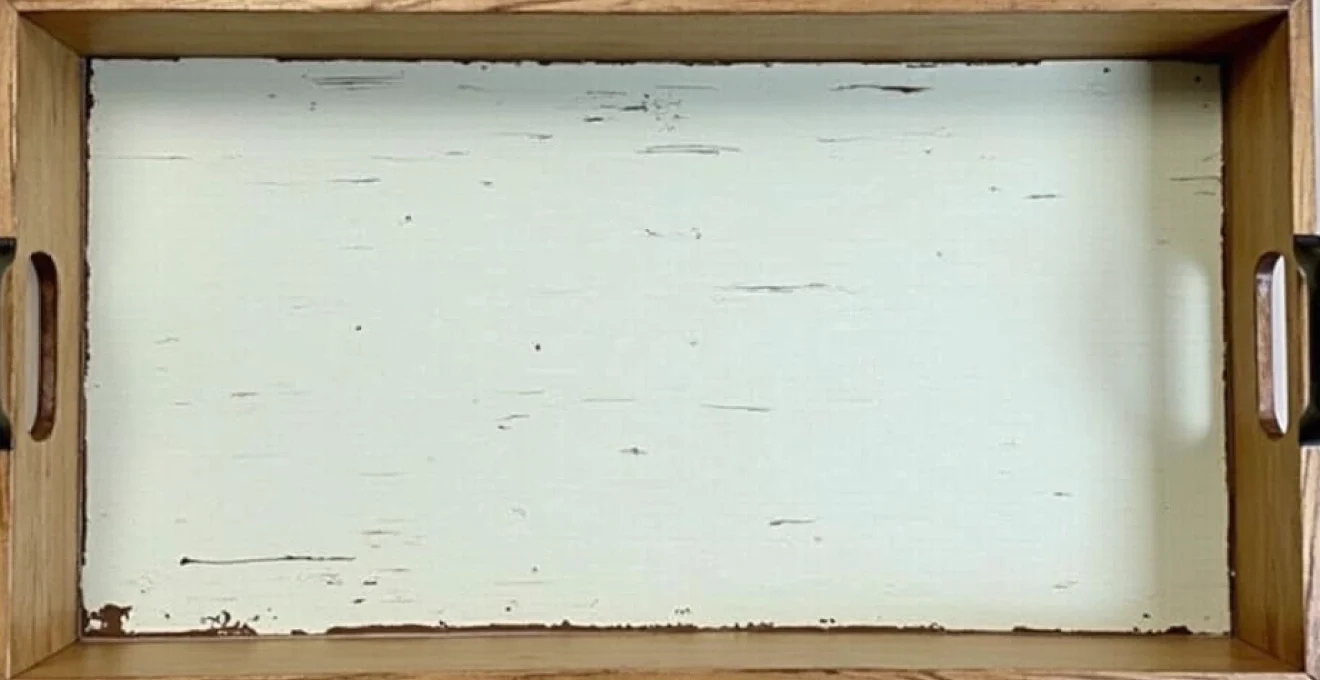

Surface finishing transforms basic frame conversions into sophisticated decorative accessories that complement existing interior design schemes. The finishing process involves multiple stages including surface preparation, primer application, decorative treatments, and protective coatings. Each stage contributes to overall appearance and durability, requiring careful attention to material compatibility and application techniques.

Colour selection influences both aesthetic appeal and practical considerations such as maintenance requirements and wear visibility. Light colours create fresh, contemporary appearances but show wear and staining more readily than darker alternatives. Deep colours provide dramatic visual impact and conceal minor imperfections but may show dust and fingerprints more prominently. Neutral tones offer versatility and timeless appeal whilst balancing practical and aesthetic considerations.

Chalk paint application: annie sloan vs Rust-Oleum coverage techniques

Chalk paint formulations offer distinct advantages for furniture and decorative projects, including excellent adhesion properties and minimal surface preparation requirements. Annie Sloan chalk paint provides superior coverage and authentic matte finish characteristics that create professional distressing effects. Its thicker consistency enables single-coat coverage over most surfaces whilst maintaining workable characteristics for decorative techniques.

Rust-Oleum chalk paint offers comparable coverage at reduced cost but may require multiple coats for complete opacity over dark surfaces. Its slightly thinner consistency facilitates brush application and reduces visible brush marks but may limit decorative technique options. Both formulations accept distressing treatments and wax finishes, though colour availability and mixing options vary significantly between brands.

Decoupage integration: mod podge dimensional magic for raised effects

Decoupage techniques create personalised decorative elements that transform plain surfaces into unique artistic expressions. Traditional decoupage involves adhering paper elements with adhesive mediums, followed by multiple protective coats that create smooth, integrated surfaces. Modern dimensional products enable raised effects that add textural interest and visual depth to finished pieces.

Mod Podge Dimensional Magic creates clear, raised coatings that protect paper elements whilst adding three-dimensional effects. Application requires careful attention to coverage uniformity and bubble elimination to achieve professional results. Proper substrate preparation and controlled application techniques prevent common issues including air bubbles, uneven coverage, and adhesion failures that compromise final appearance.

Distressing methods: steel wool grade selection for vintage aesthetics

Distressing techniques create aged appearances that suggest natural wear patterns and historical authenticity. Steel wool grades determine distressing intensity and finished texture characteristics. Coarse grades remove material aggressively and create pronounced wear effects, whilst fine grades produce subtle aging that suggests gentle use over time.

Grade 0000 steel wool provides gentle abrasion suitable for highlighting raised details and edges without removing significant material. Grade 00 steel wool creates moderate distressing effects ideal for general aging applications. Coarser grades should be used sparingly and only in areas where pronounced wear patterns appear natural and intentional.

Protective topcoat application: polycrylic vs polyurethane durability

Protective topcoats preserve decorative finishes whilst providing resistance to wear, moisture, and staining. Water-based polycrylic formulations offer clarity retention, low odour characteristics, and compatibility with diverse base coatings. Their quick drying times and easy cleanup make them ideal for indoor applications where ventilation limitations exist.

Oil-based polyurethane provides superior durability and moisture resistance but requires adequate ventilation during application and curing. Its amber tint may alter light paint colours whilst enhancing wood grain visibility in natural finishes. Professional applications often specify multiple thin coats rather than single thick applications to achieve optimal clarity and durability characteristics.

Hardware installation and functional enhancement solutions

Hardware selection and installation significantly influence both functionality and aesthetic appeal of converted trays. Handle placement affects weight distribution and carrying comfort, whilst footer installation protects furniture surfaces and provides stable positioning. Understanding load requirements, ergonomic considerations, and installation techniques ensures professional results that enhance user experience.

Handle styles range from traditional metal pulls to contemporary leather straps, each offering distinct advantages and aesthetic characteristics. Metal handles provide maximum strength and formal appearance but may show fingerprints and require regular cleaning. Rope or leather handles create casual, organic appearances whilst offering comfortable grip characteristics, though they may require periodic replacement due to wear.

Mounting hardware must accommodate both handle loads and frame material characteristics. Through-bolt installations provide maximum strength for heavy-duty applications but require access to interior frame areas. Surface-mounted hardware offers easier installation and maintenance access but may limit load capacity depending on fastener selection and substrate characteristics.

Footer installation prevents surface scratching whilst improving stability on uneven surfaces. Felt pads offer silent operation and gentle surface protection but may compress over time, requiring periodic replacement. Rubber feet provide superior grip and durability but may leave residues on certain surface finishes. Cork alternatives balance protection with natural aesthetics whilst offering moderate durability characteristics.

Proper hardware installation transforms basic frame conversions into professional-quality serving pieces that enhance both functionality and visual appeal.

Ergonomic considerations influence handle placement and sizing decisions that affect user comfort and safety. Handle height should allow natural wrist positioning whilst maintaining adequate clearance from tray contents. Spacing between handles must accommodate comfortable two-handed carrying whilst providing balanced load distribution. These factors become particularly important for larger trays intended for entertaining applications.

Troubleshooting common Frame-to-Tray conversion challenges

Frame conversion projects frequently encounter challenges that require creative solutions and technical expertise. Understanding common issues and proven resolution techniques prevents project delays and ensures satisfactory outcomes. These challenges range from structural problems to finishing difficulties that may not become apparent until project completion approaches.

Joint loosening represents a frequent issue in older frames where traditional adhesives have deteriorated over time. Moisture exposure, temperature fluctuations, and mechanical stress contribute to adhesive failure that compromises structural integrity. Reinforcement techniques include adhesive injection, mechanical fastener installation, and corner bracket applications that restore stability without compromising appearance.

Base fitting problems occur when frame rabbets exhibit dimensional variations or damage that prevents proper base installation. Custom shimming techniques accommodate these irregularities whilst maintaining secure attachment. Material removal may be necessary to achieve proper fit, though excessive modification risks compromising frame strength. Professional assessment determines appropriate correction methods that balance fit requirements with structural preservation.

Finish adhesion failures typically result from inadequate surface preparation or primer incompatibility with substrate materials. Complete refinishing may be required to achieve satisfactory results, though spot repairs sometimes prove sufficient for minor failures. Understanding the root causes prevents recurrence and guides material selection for remedial work.

Warping issues affect both frames and bases when moisture content changes occur during construction or afterwards. Controlled drying techniques and moisture barrier applications help minimise these effects, though severe warping may require professional intervention or component replacement. Prevention through proper material storage and controlled environmental conditions proves more effective than remedial measures.

Hardware installation complications arise when frame materials don’t accommodate standard fasteners or when structural limitations restrict mounting options. Alternative hardware designs and custom mounting solutions address these challenges whilst maintaining functionality requirements. Professional hardware suppliers often provide specialised solutions for unusual applications that standard retail options cannot address satisfactorily.